Low cleansing, high conditioning, and loads of suds!

© 2011 by KV5R — Rev. Jan 11, 2011.

Shop for soap making supplies here.

Goals

- Design a super-conditioning winter moisturizing soap.

- Deviate from the middle of the properties scales and make a specialty soap.

- Try an essential oil at near 3%.

Soap Recipe Designer Spreadsheet

KV5R's Soap Recipe Designer Template for OpenOffice Calc

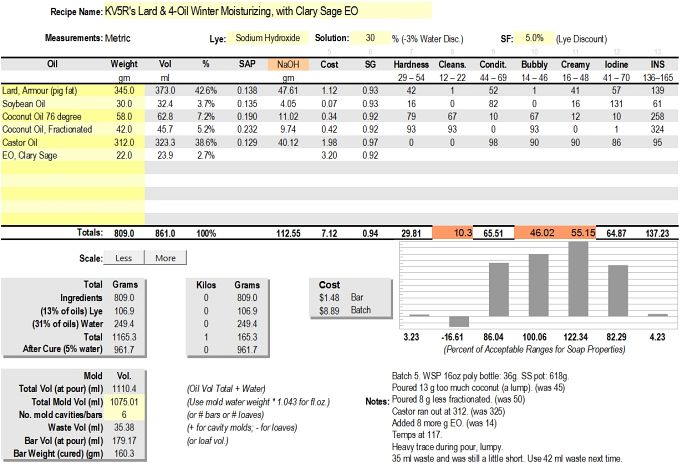

The plan was to push the cleansing way down to around 10, get the conditioning as high as possible, and make it real creamy. Given the oils I had on-hand, this meant pushing way up the Lard and Castor, and way down on the Soybean and Coconut. I would have used a lot more Soybean but it has a high iodine and, with all that Castor, it was hard to keep the iodine under 70. I read on some good soaping site (forget which one) that for a good winter soap the cleansing should be around 10 and the INS around 136, with the conditioning as high as you can get it. So that’s what I did here. The hardness is a bit under 30, so it’s gonna be real soft soap—probably a nice makeup-remover for the ladies. You can see the theoretical results in the properties in the screen shot above. Time will tell if this one’s a success or not, so check back here around mid-February (2011).

The Recipe

Developed using my soap recipe designer spreadsheet, with the goal of pushing the properties as far as possible. Don’t use this recipe ’til all the results are in.

- 345 gm (42.6%) Armour Lard

- 30 gm (3.7%) Crisco Soybean oil

- 58 gm (7.2%) LouAna Coconut oil, 76°

- 42 gm (5.2%) Crafter’s Choice Coconut oil, fractionated

- 312 gm (38.6%) Crafter’s Choice Castor oil

- 22 gm (2.7%) Crafter’s Choice Clary Sage essential oil

- About a half-teaspoon of powdered cinnamon (for a little flesh-tone color)

- 107 gm NaOH × 2.33 = 250 gm water = 30% caustic solution (a 3% water discount)

- 5% lye discount

- Target volume (at pour): ~1110 ml to fill the 1075 ml 6-cavity silicone mold and allow a little waste.

The Procedure

Same as the last batch.

Results

Same as the last batch. It was again at heavy trace by the end of the pour. My volumetric calculations were a tiny bit short. Should be targeting 1120 ml for the silicone mold. Once I get that nailed down, I’ll put a correction factor in the spreadsheet.

Four hours later: nice and hot, fully gelled.

Tomorrow: Un-molded easily, is soft (you can dent it with firm finger pressure), and the scent is light and tolerable. I always keep a little fan running on a top shelf, so I put the bars in front of it to speed the drying.

Pictures

I didn’t take pictures during the process this time. See the pictures in batch 4.

The ½-tsp of cinnamon gave it a light pinkish-lavender color, with small cinnamon dots.

How Does It Work?

Washed hands with one a few days later. Something’s wrong—cleansing is indeed low, doesn’t dry the skin, rinses easily, but it isn’t producing good lather. According to the numbers, this soap should produce gobs of creamy lather. Will check it again in a couple weeks; maybe it just needs to cure some more, or maybe I pushed the properties too far.

Concluding Thoughts

So there’s my fifth batch. What did I learn?

- It’s not easy (maybe not possible) to design a soap with high conditioning and also good hardness.

- I probably should study into using Shea and Cocoa butters and such before attempting to make another conditioning bar. (Later: I did, and the numbers and cost just don’t add up! Several common, cheap oils have better conditioning, and cost a fraction of shea and cocoa butters.)

- Even after 5 tries, I still poured a bit late!

- So far, I don’t like Clary Sage. It’s too much like a commercial soap smell.

- Adding an EO or FO nearly doubles the cost of the soap. I think I’ll just stick with powdered herbs and spices in the future. There are plenty of powdered herbs you can buy on-line for ~$7 a pound in bulk. Mixing them will yield various colors and fragrances, and they don’t mess with the reaction.

Stay tuned for more in the coming weeks.

So until the next batch, good soaping! —KV5R