Copyright © 2002, 2006 by Harold Melton, KV5R. All Rights Reserved.

Watertight Entry Assemblies

This assumes your rig is near a window, and you know how to replace a window pane with plastic. I used a window because my trailer-home has metal siding. If your walls are nonmetallic, you can, of course, go through with long threaded brass rods. This may be easier than replacing a windowpane with polycarbonate.

Remove and disassemble the windowpane. Measure the glass, then discard and replace with polycarbonate of the same thickness. Many hardware stores carry small pieces, and one shouldn’t cost over a few dollars. Cut the new plastic pane to the exact dimensions of the removed glass. Reassemble the window.

Plastic sheet is best cut with a circular, table, or radial-arm saw, using an 80-tooth finish blade (hollow-ground or carbide — do not use a “set-tooth” blade) and cool with a little trickle of water. Don’t use a jigsaw, as they just make too much heat. Apply masking tape to avoid scratches during cutting. You may be able to find a store with a commercial panel cutter that will do this for you, and save all the mess and trouble. Take exact dimensions.

Note: It is possible, with a special bit, to drill glass. Don’t! If a big storm comes along and a tree limb falls on your ladder-line, it’ll probably rip out the window glass - not exactly desirable, particularly during a storm…

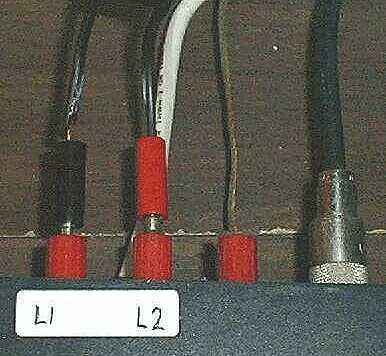

Fabricate the feed-through assemblies using 10-32 brass hardware as shown in Figure 2. You’ll need (2) 10-32 x 1½ screws, 10 nuts, 4 brass washers, and 4 flat rubber sink faucet washers (as seals). Drill the two holes through the window, spaced the same width as your ladder-line. Attach the ladder-line on each end using soldered ring lugs. Split the rings open with wire cutters, place over the outside end of screws, then close the rings and tighten the nuts. Cover outside connections with Coax-Seal (see mine corroding?).

If you’d rather go through a wall (nonmetallic houses), get the appropriate lengths of small brass all-thread rod, and the same length of Tygon tubing (the thick-walled variety) to slip over and insulate the rods. Then get the appropriate extra-long drill bit (carbide-tipped for brick, if needed). Don’t drill into a pipe or electrical wire! Drill the holes through the wall and insert the Tygon-insulated rods. Put double nuts and washers on each end. Caulk the outside entry points. Solder ring-lugs to the feedline and jumper. Grease the rings. Install and tighten. Waterproof the outside ends with silicone caulk or Coax-Seal. You’ll then have a permanent ladder-line entry that’ll last as long as your house.

Figure 2

Many people seem to miss the KISS principle. You can take a 1-by-4, cut to the width of your window, paint it with exterior house paint, wrap its edges with foam weather-stripping, put it in a window and close the window on it. Then cut a length of parting stop (door molding) to use as a jamb-stick to lock the window down against it. Then you can drill it to your heart’s content and bring in all kinds of cables, all without drilling your house. Works great for renters.

The Quick-Disconnect Jumper

The short jumper on the inside goes from the feed-through bolts to the balanced output of the antenna tuner. Solder banana jacks onto the line and just plug them in. When thunder is heard, jerk them out and bend the line well away from equipment. This is a lot faster and neater than using the cross-bores in the binding posts, and will encourage you to disconnect at every sound of thunder. However, the bananas might not handle the high current of QRO operation. Since I run barefoot, this is not a problem. A good old-fashioned double-pole knife switch is an even better option - and they look so cool!

Figure 3

2018 Update

Please see 80-Meter Doublet in the 2018 section. Lots of pictures!

— End —

Did you ever run the open wire line in the large PVC pipe underground? I have an HOA situation where I can’t place the remote tuner at the base of an OCF vertical flagpole antenna. Feeding it from the shack in coax is less than satisfactory, some 45′ of LMR-400. I would like to be able to place about 25 to 30 feet of the proper PVC and place 450-ohm window line inside to the balun on a remote tuner at the ground rods and building entry point. The two halves of the vertical are fed inside the pole with window line out to an open wire lightning arrestor and static bleed and then a common mode choke and LMR-400 to the building entry point. I would hope the replacement of the coax would make the antenna more manageable. I can’t really put the remote tuner at the base of the flagpole as it would attract the attention of the HOA cops. Any thoughts?? Thanks, Bill – K9BO

Howdy Bill,

No, I never tried it. You’ll be breaking new ground there… 😉

I’d use the 1/2″ 300 ohm line in 3″ thin-wall pvc sewer line. The main problems I imagine are how to keep the line centered in the pipe, and how to keep it completely DRY.

Let us all know if you can make it work!

73, –kv5r

Thank you for the practical information on ladder line – really nice to have all the hype dispelled!

I am putting up a store-bought ZS6BKW 80m-6m antenna (92’ long) and part of the design of the antenna is that the 450 ohm ladder line drop section is a certain length (41’). This line is then terminated with a 1-1 balun in the antenna I have (although the antenna designer says that this balun is not necessary and that a coax feed can be attached directly to the end of the ladder line section). The distance from this balun to my transmitter is then around 55’. My question is does the length of coax cable make any difference in this situation, especially as I would prefer to use the antenna without the use of a tuner? I currently use a 100w transmitter but am restoring a Kenwood TL992A linear amp, so will be using significantly more in the future. I read somewhere that the coax should be at least 70’ long but this hobby is rife with tribal knowledge, so your advice would be sincerely appreciated.

Thanks,

Mark Allen

KK6AFD

Howdy Mark,

I don’t know about the ZS6BKW, but like the G5RV, any coax you use will be quite lossy when operating on bands where the SWR on the coax is high. On the (4?) bands where SWR is low, coax length shouldn’t matter, Z will (hopefully) be close to 50 ohms.

Just try what you have and see how it acts.

73, –kv5r

I passed two 3/16″ steel rods through my wall (stucco on the outside and drywall on the inside) to bring my ladder line inside the shack. The rods are only about 5 to 6 inches long and are spaced the same width as the ladder line. Both rods have a thin layer of electrical tape on them due to the chicken wire inside the stucco. The outside connection is protected from weather; otherwise, my climate is very dry here in So. Cal.

Everywhere I read about this technique refers to brass threaded rods, but I used steel and they seem to work fine. Am I overlooking something by not using brass for this connection?

Well, no, other than steel will eventually rust. Grease your connections. The resistance of steel vs brass is inconsequential in such a short run.

I made another entrance with 3/8ths Tygon tubing, see https://kv5r.com/ham-radio/2018-projects/80-meter-doublet/ .

Thank you for your quick response. I have some dielectric grease that I will put on the outside connection.

73 de K3SZ

Is it necessary to terminate the ladder line on the outside of the house? Why not run the ladder line from the antenna, all the way to the tuner?

Howdy Roger,

Putting the balun outside is just a matter of convenience, for (1) single-hole coax entry; (2) easy disconnect during storms; and (3) outside grounding.

Please see my 80 Meter Doublet article, where I brought ladder line in to tuner, then came in with twin coaxes (easier to disconnect), and finally, put a balun outside and came in with coax via a grounded bulkhead fitting.

It’s really just a matter of personal preference and practical considerations.

73, –KV5R

I am reading your article on ladder line with much interest. I am planning a horizontal loop around the perimeter of my small yard. With luck, I might be able to manage 200Ft, roughly rectangular shape (with a slight zig-zag or two) . The goal is to use it to get on a MARS frequency between 4 and 5 Mhz without being too far out of resonance. I was about ready to attach ladder line but a local ham thinks it could be a problem. I was planning ladder line from the feed point to within about 10 feet of the shack and then 4:1 current/choke balun (DXE-MC20-C4-1) and coax into the shack. My friend thinks running ladder line close to the shack and parallel to one of the legs , is asking for trouble. He suggests bringing the ladderline almost at a 45 degree angle from the loop , just about 25 feet of ladderline, to the 4:1 balun and then run coax from the balun to the shack for 35-40 feet. Everything I have read suggests a “short” length of coax after the ladder line. I’m a bit nervous about having the coax run actually longer than the ladder line. I would appreciate your thoughts.

Andy K3UK

Sorry, a typo. “close to the HOUSE” for 35-40 feet is my friend’s concern. NOT close to the shack.

Run you ladder line to the shack (choke/balun) and keep the coax from balun to tuner as short as possible (2-8 feet is OK).

The only concern with running LL close to house is picking up noise from stuff in the house. A good choke/balun will stop most of that common-mode noise.

The LL will not radiate RFI into the house if it’s terminated into a balanced antenna (center-fed dipole or loop).

73, –kv5r

That makes me feel less anxious about my plan. Raid delayed me today so I have the benefit of your input. Many thanks.

Andy K3UK

but your comment about a “balanced antenna” and centre-fed loop is making me think. I was planning to add the LL at a convenient corner of the rectangle loop closest to the shack , are you suggesting I try to attach LL at a point where an equal amount of the loop is on either side of the LL point ?

A loop is balanced no matter where you put the feed point.

What are the issues, if any, of stapling my ladder line to drywall?

Should be no problem, for 1″ window line, if you avoid running parallel to wires and pipes in the wall. If you’re gonna run open-line (3-6″), be aware the outer walls might have metal-clad sheathing on the outside, between the studs & brick/siding, that would be too close for the wide-spaced line.

As an alternative to threaded brass rod, you can easily cut threads on small gauge copper tubing (1/4″ or so) with a tap & die set. Use brass, bronze, copper, or stainless nuts & washers. Brass is 28% as conductive vs copper, bronze even less so. Copper tubing can also be bent which might be useful for some. 73 – K4HSB

Yay, a good article with several topics on which I needed info. The 1/8 wave part might be particularly helpful. I’ve had rf in the shack since I changed to 450 ohm open Wire. I’ve tried to choke it out, no luck. Only problem is with a cheap QRP rig I’ve built and operated which uses a VERY inexpensive arduino. It seems to get into the lines of the arduino. So I’ll be trying different length options. I’m running, at this time , a delta configured horizontal 80m sky wire. Beautiful antenna, so little noise its amazing. Thinking about going to 160 length. I run an auto tuner and its amazingly quick and efficient. D4C from California , 5 watts usb 15 meters for instance ! Having a ton of fun since I went this direction, so thanks for your help !

The arduino based rigs need a steel case and toroids on all in/out lines. Think: cmos processor, nearby antenna… Those kits are not complete until you do proper RF shielding & choking.

Ladder line will not radiate if it is terminated in a balanced load. Center-feed.

Hello Sir,

I am a fairly new Ham and I have a limited space lot so I want to build a homemade 450 Ohm Ladder line to form the Dipole and then to feed the antenna,but I am Having trouble finding the Spacing of the 2 #14 Stranded conductors,can you please advise me as to the separation side to side?

Thank You and 73

Hello Bob!

It’s not at all critical; anything from 1 to 6 inches will work. With 1″ spacing the impedance is around 400-450, with 4″ it’s about 500, with 6″ it’s about 600 — not that it matters, since with a multi-band doublet the impedance is all over the place and the antenna tuner (hopefully) fixes it at the radio end.

With closer spacing, you have a smaller diameter magnetic field, but you also need more spreaders (like 1 per foot) so it won’t twist. With wider spacing the magnetic field is larger (keep it 3 times its width from metal), but you can use fewer spreaders without any twisting problem.

I made 4″ line, with Zareba (or Fi-Shock) fin-tube electric fence insulators and cable ties, every 4 feet, and it works well but I wish I’d put them every 2-3 feet, as the SWR wiggles just a bit when the wind blows the spacing around.

73, –kv5r

Oh, I’m in a Lightning Zone. Was a commercial Comms guy. Polyphaser is a commercial version protector that may save your station. Used on mountain tops. For the home, a good lightning rod system is recommended, on top of your tallest tree, with heavy wire all the way to the ground and a good ground rod. Rather than discharging with that all powerful “lightning flash”, it discharges the static zone around your property. You can actually hear it discharge, a zzzzzzzzz, although I have had static electricity re-program radios. Best to ground the antenna if possible when that huge storm is around but on mountain tops we had to rely on good ground rods and polyphasers on each and every antenna, also we loose dipole loop arrays. DC grounded to the tower. five or six ground rods at the tower, heavy wire.

Yes, and 6″ copper flashing is better than any size ground wire. Silver-soldered or cad-welded to the rods.

ladder line Question do they make ladder line spacers to make your one line?

do they make 18 awg ladder line and where to buy?

Ps how do you install ladder line on your ft2000mp?

Jerry webster

4705 Hyada blvd Ne

tacoma wa 98422 Ph 253 927 1320

There’s a spacer called “LadderSnap” that snaps onto the wires. I used Zareba 4″ fin-tube insulators and 11″ cable ties.

TheWireMan is a good source for window line.

With a 1:1 choke/balun and an antenna tuner.

Harold,

I am putting up a 160M doublet with 600 ohm ladder line. Will the insulated antenna wire I am going to use eliminate the static buildup problem because the wire is insulated? Thanks, Todd K1TOD

Yes, insulated wire is generally quieter, wind & rain static-wise, than uninsulated. Also lasts longer. But insulation does nothing to reduce HV induction pulses from nearby lightening, or that 60Hz grinding from noisy power lines.

Have a 160m shortened dipole using around 42′ of Nr 14 450ohm LL feed to a 1 to1 current balun and 6′ of RG 213 to a HF Auto tuner all is well with this setup. Question what is the next leanth LL that could work for 160-75-40m only could use about 90′ or less over all to do this job! This would raise the apex about 13′, it I could make it work. Thanks walter kb6hrt

Any length will work if you’re not having RF in the shack.

80′ is the next length that’s non-resonant in common-mode on all hf bands. See page 3 of this article.

73, –kv5r

Great website, and I especially liked the ladderline article. I have been using ladderline for many years to feed my loop. Just wanted to mention that Zareba products make a superb 4 inch fin tube insulator for use in electric farm fences. These fin tube insulators make EXCELLENT spreaders for ladderline, being UV resistant, lightweight and extremely strong. Google online for a picture. Prices are very reasonable, about 10 cents each. Find therm in your local Farm and Feed store, in the electric fence department.

Thanks John, that’s a great idea! I’ve looked at electric fence supplies before but didn’t notice they made 4″ tube insulators.

I’m curious as to how you attach them to the wires, drilled holes, or notch and glue, or ?

73, –kv5r

Hi. sorry for the long delay in replying, I drill holes about 1/4 inch in from each end, just big enough for the insulated wirte to slip through. couple of drops of PVC glue or epoxy, will keep them secure.

A few weeks ago I made 155′ of line using the Zareba fin-tube insulators. Attached them to the wires with the thin 11″ cable ties. Run tie thru, around wire, back thru, and around other wire. Works well; easier than notching or drilling.

73 & Thanks for the tip!

–kv5r

Great site Harold. I have a nice 80 meter inverted vee doublet up 65’on fiberglass telescoping mast fed with DXE’s 300 ohm ladder line to either 1:1 or 4:1 Palstar current balun, then short coax to Palstar AT2K tuner.

First question: it would be very convenient (and out-of-weather) to run the ladder line down the *inside* of the (non-conductive) mast but I have read several negative comments about the inefficiencies of running non-coaxial feedlines through PVC, etc especially if buried. I’ve tried running ladder line inside the mast and know it works, but does this increase losses, etc?

Second question: I would like to try this 80 meter antenna on 160 by running it against ground or counterpoise as a “T” or as a top hat loaded vertical or just half of it as an inverted “L”. The ladder line would ideally be run up the inside of the mast. Obviously a single conductor is called for instead of ladder line. Would it work to just short the two conductors together at the station end or would the top leads need to be shorted also (or vice-versa)? In the case of the inverted L, would it work to feed just one conductor and ignore the other half of the line & antenna?

Please reply by regular email.

Thanks so much! 73 – Jim, K4HSB

Hi Jim,

You should be able to run your LL up thru your fiberglass mast without much loss; it depends on the dielectric constant and thickness of the mast. But don’t run it underground thru PVC, that doesn’t work, the earth around the pipe soaks up induced power from the line’s magnetic field. You’d need to cut a slot in the mast some distance above ground to bring the LL out, and that might weaken the mast. I wouldn’t risk it.

To run your 80M dipole on 160, tie both leads together at the balun and ground the other side of it. Don’t run one wire only, the other one will sap power by induction. Tie both leads together (common-mode). You don’t need to short the top end.

You could use a heavy-duty DPDT switch at the balun; one pole of the switch would swing the ground from balun to nothing, the other pole would swing one side of the LL from one balun output post to the other, where the the other LL wire is connected. Just make sure the switch has enough air-gap in it so RF doesn’t arc, if you run high-power. A good ol’fashion knife switch, or an RF relay would be even better.

I’ve never run that configuration but lots of top-banders do. With your mast/feedline vertical 65′ and the dipole as a top-hat it should work pretty well as a 1/8th-wave top-loaded vertical. Lots of 1/4-wave ground radials at the base of the mast will help, if you have the space (that’d be like a couple acres!) but if you have room for 130′ radials, you have room for a 160M dipole, which, peaked at 65′, would work a lot better than a vertical w/o radials.

I’m curious where you found a 65′ fiberglass mast. The longest ones I’ve seen on-line are like 48′, at ~$300.

73, –kv5r

Thanks Harold,

You can make the mast out of tubing from DX Engineering but if you go the full 65′ that way it is pretty flimsy way up there and needs lots of guys.

I’m running the first 20’with pressure-treated wood and the rest with the fiberglass starting with 2.75″ diameter. The antenna itself serves as top guys and one other set mid-way. It survived an F1 tornado intact!

73, Jim, K4HSB

You got an amazing site, my friend! I have never seen so much relevant and “down to earth” info in one place. I really appreciate, and it strengthens my belief I had in home-brewing ladder lines and doublets. I run a 80 feet doublet, from the balcony of my 24th floor apartment till the roof on the 26th floor. I use NO line…the antenna starts at the tuner LOL! A refurbished AH4…..Thanks again, and keep up the good work. 73 from India, DE VU2ORO, Ron!

I have a 2″ pvc pipe thru my wall which I bring coax etc into shack. My house is all metal can I place the 4:1 balun out side and use 10 foot coal into the tuner. Really liked your article.

David KD9ALS

Yes, that’s a very commonly used way of doing it. Years ago, I brought ladder line to the house, coiled about 7 turns of it bifilar on a 1.25″ type 77 Amidon toroid, then used about 15 feet of RG-8 coax from there on in and it worked OK. When I eventually made the change to bringing it all the way into the tuner (as drscribed in the article), it did work just a bit better.

Harold,

Nice series of articles on balanced transmission line. Thank you. I’m thinking about the vinyl covered galvanized steel wire rope for the transmission line and elements of an all band dipole. The material is very strong, flexible an solders willingly. The vinyl clad coating should increase its usable life. It’s available in a variety of gauges. What are your thoughts?

I haven’t tried it or known of anyone who did, but it should work; the resistance will be several times higher than copper so size it up accordingly.

Thank you for taking your time to compile your knowledge of ladder line and put it out here for us to read. I have been using ladder line for about a year. I like it much more than coax. I have two doublets. An 88′ and 44′. They perform as Double Zepps on 20m & 10m, but they tune up on all bands except 160m. I run 450 Ohm ladder line straight to the tuner. My tuner has a “Balanced” button on it that puts the signal through a 4:1 balun. (I’m sure you know that) Anyway, I have some bands in which I get a better tune when NOT engaging the “balanced” button. Is this ok for me to run it like this on those bands? I would think it’s ok. But after seeing your site, I thought I’d run it by you and see what your thoughts are this.

Thanks Kirk / wt4p

If some bands tune better without the 4:1 balun in-line, then fine. I think that would mean the impedance of the line, at that point and frequency, is closer to 50 than 200.

I’m a new ham designing my first station and I liked your ladder line article. Now, if possible, your suggestion on how to get the ladder line into the shack. I have a metal building that I installed a stainless steel water tight enclosure on the outer wall. There are 2 1″ holes cut into the door of the enclosure that I will use to bring ladder line/antennas in. I’m building a doublet dipole antenna 135′ long. I will have a 4:1 Balun between the ladder line and a tuner.

1. Should the balun be mounted outside of the enclosure?

2. If I bring the ladder line inside the enclosure are there insulators available to go through the holes? Will I be too close to metal?

Suggestions welcome

I think it would be the same as an antenna tuner box that has insulators in the back and a balun inside. You should be able to bring the ladder line into the box with a couple of insulated 8-32 threaded brass rods, connected to the balun inside, then go out the back into the building with a short run (say, <~15') of coax to your tuner. The balun should be inside the box, but make sure to use a current balun (has 1 or 2 toroids), not a voltage balun (has coils usually wrapped on pvc). I'd blank off those holes in the door and bring cables in through individual, grommeted holes in the bottom - better to keep out bugs and moisture. And coming in the bottom forces you to leave a drip-loop in the cables. Then put the ladder line insulators thru the side or door. Many insulators are available, (search for RF feed-thru and feed-through), but it's easy enough to make your own, something like: rubber grommet or nylon bushing in the hole; nylon washers and double brass washers and nuts on each side; 8-32 brass rod thru the middle. Grease and waterproof the outer connections. Should work fine. If you're using solid-wire line, wrapping it is OK, but if it's stranded, terminate it with soldered ring-lugs. Could also mount a little metal plate there, on a stand-off block or bolt, very close (like .025") to the outer nuts, as a spark-gap arrestor. Then ground the box with a fat wire to a ground rod right below it. Ladder line is unaffected by crossing metal perpendicularly; what you want to avoid is running it for some distance parallel to metal, less than about 4" away. For example, if you're gonna come down the side of you metal building, simply make 6" stand-offs with L-brackets and 1/2" pvc pipe. I used the same to come 20 feet down a tower leg and it was unaffected. Hope this helps, and thanks for stopping by! --kv5r